Company

Teraon strives for sustainability by engineering energy-efficient materials and products with continued innovation efforts

in advanced materials science, heater design/manufacturing technology, and sensor integration technology.

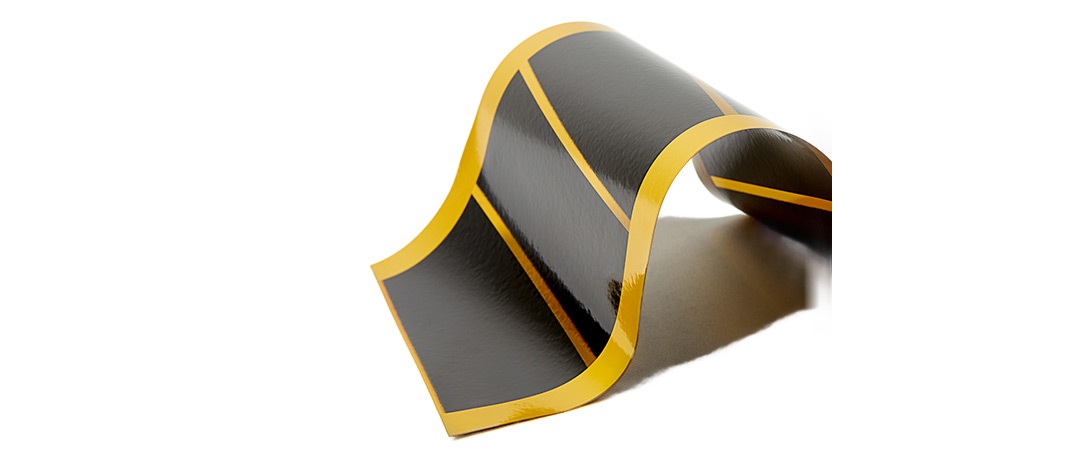

Teraon is a market leader in industry of nanocarbon-based infrared radiation warmers for interiors of electric vehicles(EV). Teraon provides a safe and efficient solution that best meets the customer needs with its proprietary technologies in heating material and in-house capabilities in all aspects of product development.

Additionally, Teraon boasts unrivaled technology of die attach paste for compound power semiconductors. The non-pressure material, which exhibits a thermal conductivity of over 150W/mk, can be applied to chips with areas larger than 5x5mm2. Currently, Teraon is undergoing a product certification offered by a global power module company.

History

Teraon’s History

Since its establishment in 2018, Teraon has made great strides in innovating new-era materials and ensuring the best product quality. In particular, in 2022, Teraon made a significant leap and emerged as one of the key players of the industry by synergistically partnering with SK Siltron.

Technology

Partnership with

Hyundai Motors

Through ongoing partnership with Hyundai Motors, we have accumulated extensive know-hows and experience. We developed nano-carbon film heaters for novel heating systems that are implemented in Genesis’s concept vehicles and Hyundai’s heritage models.

Intellectual Property Rights

-

Domestic

Patents- Registered 25

- Applied 26

-

Foreign

Patents- Registered 0

- Applied 10

-

Domestic/Foreign

Design Rights- Registered 3

-

Domestic/Foreign

Trademark Rights- Registered 6

R&D

Through ceaseless research and development(R&D) efforts,

Teraon accumulated expertise in the field of advanced materials technology.

TERAON’s Core Technology

Material Design Technology

-

Design of composite material composition

Control technology for electrical and mechanical properties based on the particle size, composition, density, surface area, and shape.

Control of rheological, chemical, electrical, and mechanical properties based on polymers, oligomers, monomers, and solvents.

-

Optimization of contradictory properties

Optimization of conflicting properties, such as achieving both heat resistance and flexibility simultaneously.

-

Design of additive and binder systems

Control technology for dispersion, leveling, color variation, storage stability, and other properties based on additives.

Nanodispersion and Compounding Technology

-

Nanodispersion technology

Selection of optimal mixing ratios for paste manufacturing, mixing process for achieving optimal dispersion, and control technology for 3 Roll Mill process.

Evaluation Technology

-

Evaluation technology

Property and durability evaluation technology specific to application areas.

Advanced Materials

Management Philosophy

TERAON is an affiliate of SK and shares SK’s management philosophy.

Management Philosophy(SKMS)

We pursue the happiness

of our members and all

stakeholders surrounding

the company at the same time.

SKMS, first established in 1979, is composed of

SK’s management philosophy and methodology for

implementing it in real management.

Through consensus and sharing among SK

members, it has become the foundation for

building SK’s corporate culture.

SKMS Talent Philosophy

We are people who pursue SUPEX through VWBE to achieve the happiness of stakeholders.